TESCAN UniTOM HR

General Information

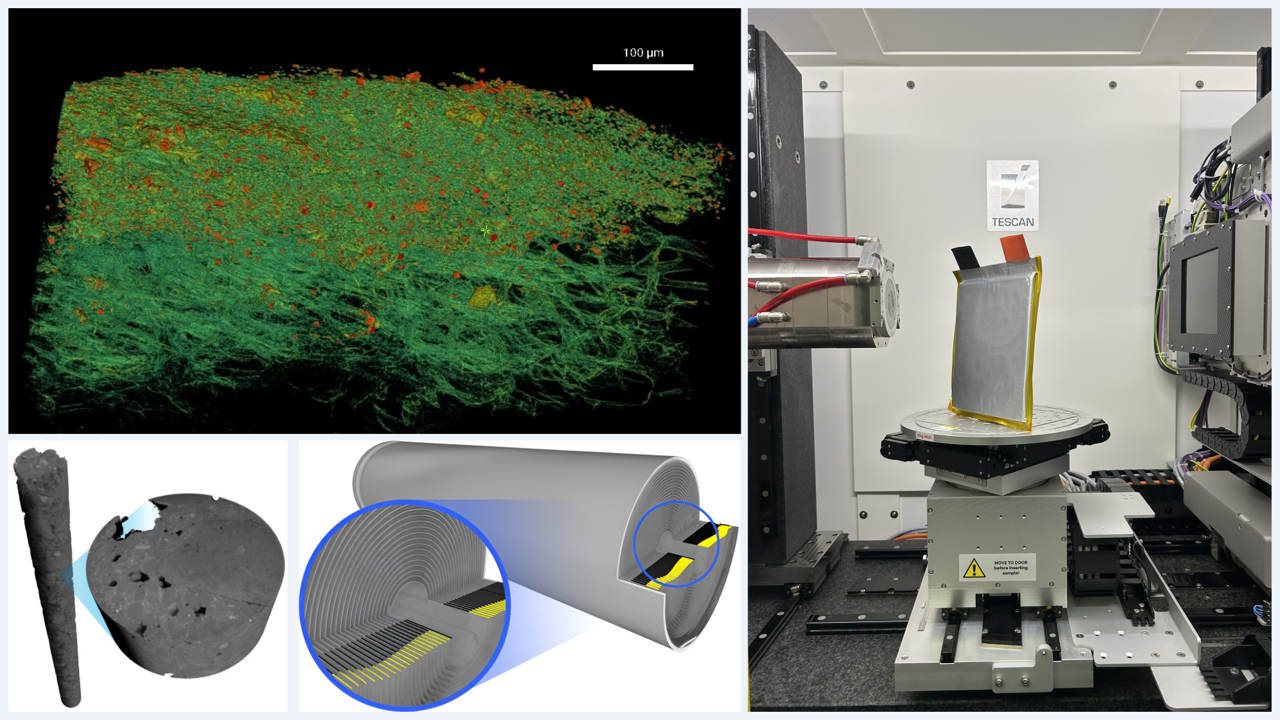

The TESCAN instrument enables multi-scale X-ray imaging with spatial resolution ranging from tens of microns down to the sub-micron level (around 600 nm), supports continuous 360° rotation and in situ experiments and it is designed for dynamic studies. The system accommodates large and heavy samples (up to 300 mm in diameter, 400 mm in height, and 45 kg in weight) and features multiple detectors, to tailor the acquisition for both highly and weakly attenuating materials. In materials science, the instrument is employed to study microstructures, porosity, cracks, and phase distribution in metals, ceramics, and composites. It plays a key role in additive manufacturing, where it is used for quality control and defect detection in 3D-printed parts. In the geosciences, the UniTOM HR allows for the analysis of rock porosity, mineral inclusions, and fossil structures, supporting studies of reservoir properties and fluid flow. In battery research, it is used to investigate electrode degradation, dendrite formation, and changes in icrostructure during charging cycles. of reservoir properties and fluid flow. In polymer science, it aids in analysing foams, fibers, and fracture behaviour. Finally, in civil engineering, it is used to assess the microstructure of concrete, crack formation, and moisture transport.

Technical description

TESCAN UniTOM HR is a micro-CT system that enables multi-scale X-ray imaging with spatial resolution ranging from tens of microns down to the sub-micron level (around 600 nm). Designed for dynamic studies, it supports continuous 360° rotation and in situ experiments. The system accommodates large and heavy samples (up to 500 mm in diameter, 700 mm in height, and 45 kg in weight) and features multiple detectors, to tailor the acquisition for both highly and weakly attenuating materials. The maximum imaging envelope is 400 mm in height and 300 mm in diameter. Advanced software tools support dynamic data acquisition, reconstruction, and 4D analysis. Additionally, the control software allows users to configure and perform full-object scans as well as multiple high-resolution zoom scans on selected regions of interest.

Research areas and applications

X-ray micro-CT has a wide range of applications, including materials characterization for battery research, cultural heritage studies, geological and palaeontological investigations, biomedical studies on small animals and plants, and non-destructive testing of various objects. This specific system is particularly suited for time-lapse and continuous dynamic scanning, enabling real-time observation of sample evolution. X-ray micro-CT has a wide range of applications, including materials characterization for battery research, cultural heritage studies, geological and palaeontological investigations, biomedical studies on small animals and plants, and non-destructive testing of various objects. This specific system is particularly suited for time-lapse and continuous dynamic scanning, enabling real-time observation of sample evolution. In materials science, the instrument is employed to study microstructures, porosity, cracks, and phase distribution in metals, ceramics, and composites. It plays a key role in additive manufacturing, where it is used for quality control and defect detection in 3D-printed parts. In the geosciences, the UniTOM HR allows for the analysis of rock porosity, mineral inclusions, and fossil structures, supporting studies of reservoir properties and fluid flow. In battery research, it is used to investigate electrode degradation, dendrite formation, and changes in microstructure during charging cycles. The instrument is employed also in life sciences, enabling high-resolution imaging of bone and soft tissue, vascular networks, and biological morphology without sectioning. In the pharmaceutical sector, it supports the characterization of tablets, coatings, and drug delivery systems. Applications extend to archaeology and cultural heritage, where the system provides insights into the internal composition of artifacts and ancient objects without damage. In polymer science, it aids in analysing foams, fibers, and fracture behaviour. Finally, in civil engineering, it is used to assess the microstructure of concrete, crack formation, and moisture transport.

Science highlights

F. Tavola, G. P. De Gaudenzi, G. Bidinotto, F. Casamichiela, A. Pola, S. Tedeschi, B. Bozzini, ChemSusChem, 18, e202402218 (2025). https://doi.org/10.1002/cssc.202402218

F. Gatti, F. Mirani, D. Mazzucconi, A. Pola, M. Passoni, IEEE Transactions on Instrumentation and Measurement, vol. 73, pp. 1-12, 2024, Art no. 3536912, https://doi.org/10.1109/TIM.2024.3472852

F. Mirani, A. Maffini, F. Casamichiela et al., Science Advances Vol. 7, No. 3 (2021) https://doi.org/10.1126/sciadv.abc8660

F. Verducci, L. Cultrera, E. Colombo, A. M. Fontanilla, F. Casamichiela, A. Pola, A. Casalegno, A. Baricci,

“A coupled dynamic PEM fuel cell and cerium migration modelling analysis to explain the experimentally measured in-plane redistribution of radical scavenger during real-world automotive operations”, to be submitted to Journal of Power Sources

Experimental team

- Andrea Pola

- DENG-POLIMI

- Professor

- Davide Mazzucconi

- DENG-POLIMI

- Researcher

- Francesco Casamichiela

- DENG-POLIMI

- Technician