FIB SEM XB340

General Information

Unit

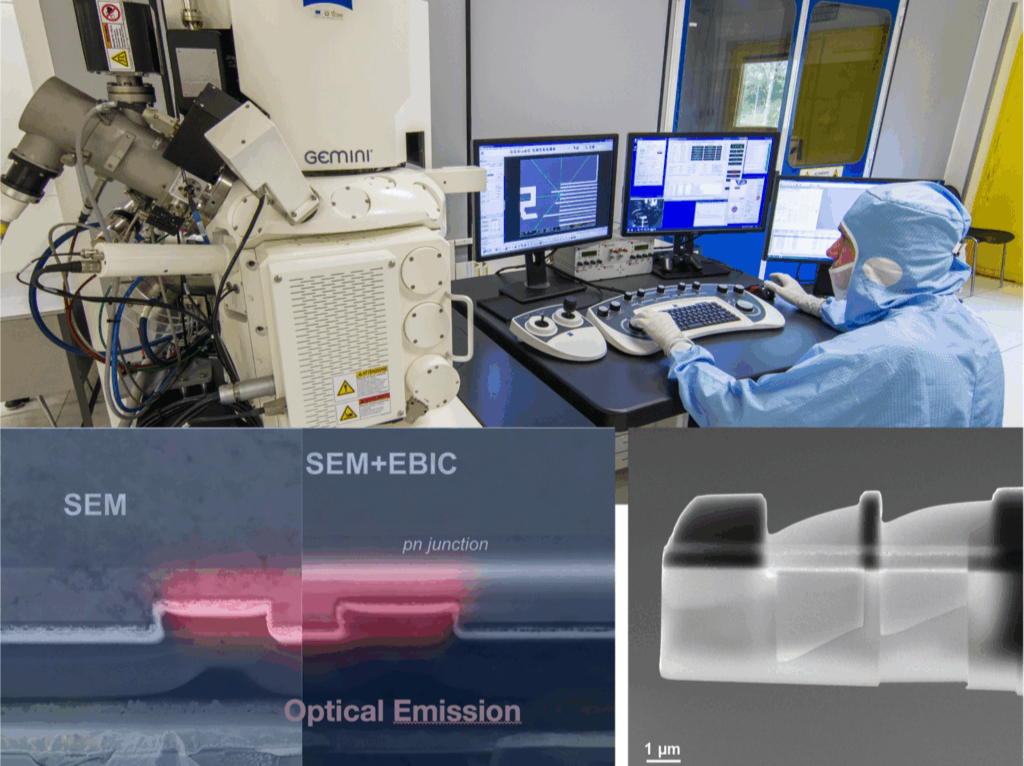

CNR-ISMNThe ZEISS Crossbeam 340 is an advanced FIB-SEM (Focused Ion Beam – Scanning Electron Microscope) platform designed for high-resolution material characterization and nanoscale patterning and fabrication. It combines a high-performance Gemini I SEM column (up to 30 kV) with a high-current Ga+ ion beam column (up to 100 nA), capable of of 1 nm resolution for SEM and 3 nm for FIB. It includes a multi-channel precursor injection system for selective electron beam induced deposition. A high-resolution pattern generator is implemented in the SEM column for controlled patterning of microstructures, complementing the direct fabrication capability with the conventional lithographic process. A set of two independent nanomanipulators with low current probing capability are used for in-situ testing of the electrical characteristics of the samples. The FIB-SEM is ideal for applications in materials science, failure analysis, microelectronics as well as the preparation of high-quality TEM lamellae allowing accurate identification of the region of interest (ROI), surface preservation through the deposition of protective layers and uniform thinning and polishing minimizing the formation of artifacts.

Tecnical description

The ZEISS Crossbeam 340 FIB-SEM system is a high-resolution dual-beam platform integrating focused ion beam (FIB) capabilities with quantum-scale electron beam lithography (EBL). It features a Gemini I field emission SEM column for high-resolution imaging and a Ga⁺ ion column operating between 5 and 30 keV, optimized for precision milling, cross-sectioning, and nanofabrication. The system is equipped with InLens and secondary electron (SE) detectors, enabling simultaneous high-contrast imaging of surface morphology, local composition, and fine nanostructures. A 5-channel Gas Injection System (GIS) allows site-specific gas-assisted deposition and etching using precursors such as Pt, SiO₂, C, Si, and additional silicon oxide compounds, enhancing material contrast and patterning capabilities. A RAITH ELPHY module is integrated for quantum-scale electron beam lithography, enabling high-precision patterning down to the nanometer scale. The system also includes Kleindiek MM3A nanomanipulators, which facilitate in-situ manipulation, electrical probing, and TEM lamella lift-out with high spatial accuracy.

Research areas and applications

The ZEISS Crossbeam 340 FIB/EBL system is employed across a wide range of advanced research fields thanks to its combination of high-resolution imaging, ion milling, and electron beam lithography. In materials science, it is used for microstructural analysis of ceramics, metals, coatings, and composites, as well as for high-resolution 3D FIB-SEM tomography, enabling the reconstruction of porosity, grain structures, and interfaces. It plays a key role in the site-specific preparation of TEM lamellae from fragile or complex materials such as porous, thin films, polycrystalline or extremely hard materials allowing for the preparation of almost all the materials of interest in the field of material science. In microelectronics, it is employed for failure analysis, cross-sectional imaging of semiconductor devices, and localized circuit modifications through FIB milling and selective deposition. In the field of nanofabrication, the integration with the RAITH ELPHY system enables ultra-high-resolution electron beam lithography, suitable for the prototyping of quantum devices and nanostructured functional materials. investigating catalytic and porous materials. Lastly, it is particularly valuable in the study of two-dimensional materials and quantum devices, enabling nanoscale patterning, manipulation, and heterostructure fabrication. This configuration makes the Crossbeam 340 highly suitable for advanced applications such as site-specific TEM lamella preparation, 3D tomography, material contrast enhancement, failure analysis, and quantum device prototyping. The combined FIB/SEM/EBL capabilities provide unmatched versatility for nanoscale research in materials science, microelectronics, and nanofabrication.

Science highlights